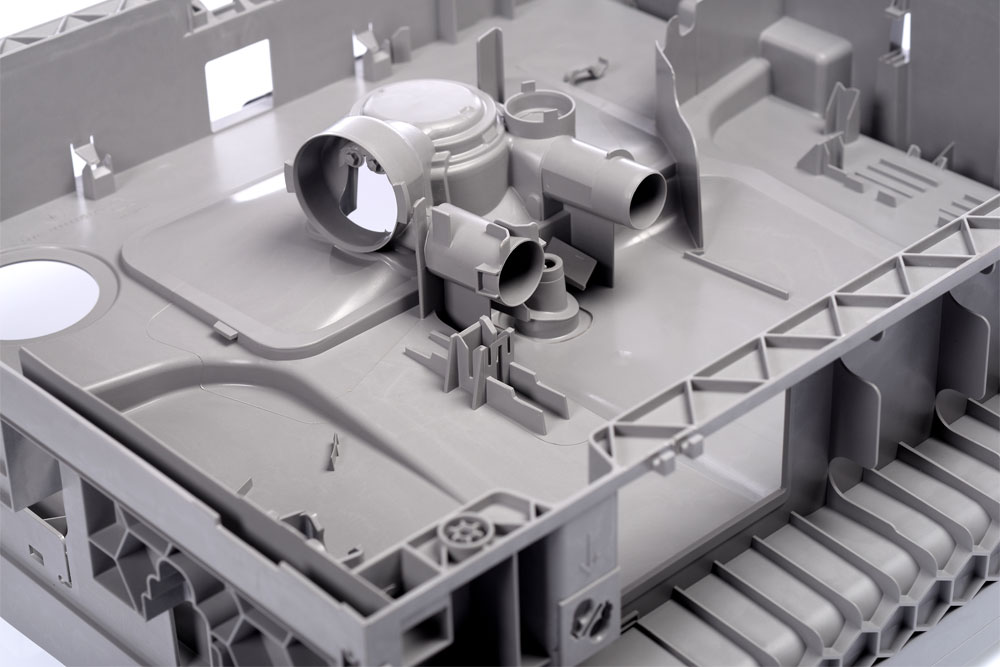

Plastic injection

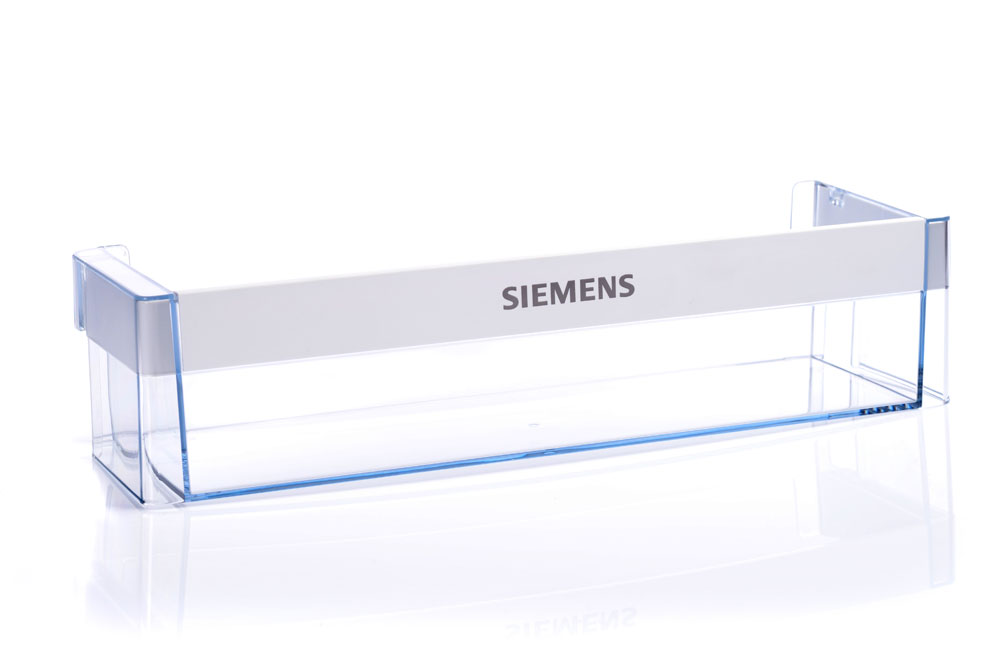

We manufacture plastic parts with all types of finishes

Injection

Standard

Plastic injection is the most suitable process for the manufacture of high-consumption parts. It allows us to transform raw materials into a finished product in a single step.

Injection

Gas

Injection

2K

Maximum quality

Finishes

Ultrasonic welding

Fast and economical technology when it comes to the fusion of thermoplastic parts.

Vibration welding

Solutions for multiple applications that enable the fusion of parts of any shape.

Component assembly

Pieces completely finished and assembled according to our clients' specifications.

Serigraphy

High printing versatility, it accommodates a wide and varied possibility of formats.

Pad printing

Great advantages for multi-color printing online with very competitive costs.

Thermo-engraving

Technical application by heat and metallization and other effects on smooth or embossed surfaces.

High capacity

Our resources

We have the human capital and facilities necessary to respond effectively and efficiently to the needs of our clients.

Our teams, all equipped with robots, include standard injection machinery as well as special and advanced two-component injection and gas injection processes.

- Injection machines: Krauss Maffei + Demag +Engel + Ferromatik + Negri Bossi

- Closing force: From 50 to 1300 T (21 injection machines)

- 2 component injection in 1300 350 and 80 T

- Gas injection on 1300 850 480 and 350 T

- Injection experience with: PA PP PS PE POM PPS ABS PMMA TPV

They trust us

Customers

Large and medium-sized companies of renowned international level trust us.

At INPLASTIC we consider that our clients are the best guarantee of our professionalism.